Environmental Recovery Facility Design

At Western Steel, we specialize in providing Solutioncentric™ engineering services for large and complex steel building projects throughout North America.

- Size: 110,250 SQ. FT.

- Location: Spanish Fork, Utah

- Application: Transport Station Expansion

In the realm of solid waste management, South Utah Valley Solid Waste District (SUVSWD) focuses on advancement. Its transfer station highlights the region’s commitment to both the environment and its growing population

The Evolution of SUVSWD’s Transfer Station

When the Transfer Station first opened its doors in February of 1990, it was a watershed moment for Utah. This state-of-the-art transfer station, a brainchild of HDR Engineering, was the very first of its kind in the Beehive State. Constructed with foresight, the facility was tailored to handle a whopping 250 tons of waste daily. Fast forward to the present, and the SUVSWD transfer station effortlessly manages approximately 700 tons per day. The past decade’s population boom led to the acquisition of an additional compactor, ensuring the station’s capability to accommodate the valley’s rapid growth and now comfortably manage over 700 tons a day.

Positioning for Cost-Effectiveness

One of the many reasons transfer stations like SUVSWD’s are incorporated is their cost-effectiveness. Ideally located, they lead to reduced labor costs. The reduced transit time means crews can allocate more hours to waste collection and less on the road. The subsequent lesser wear and tear on garbage trucks further trims down city fleet maintenance costs.

The New Addition: Environmental Recovery Facility Design

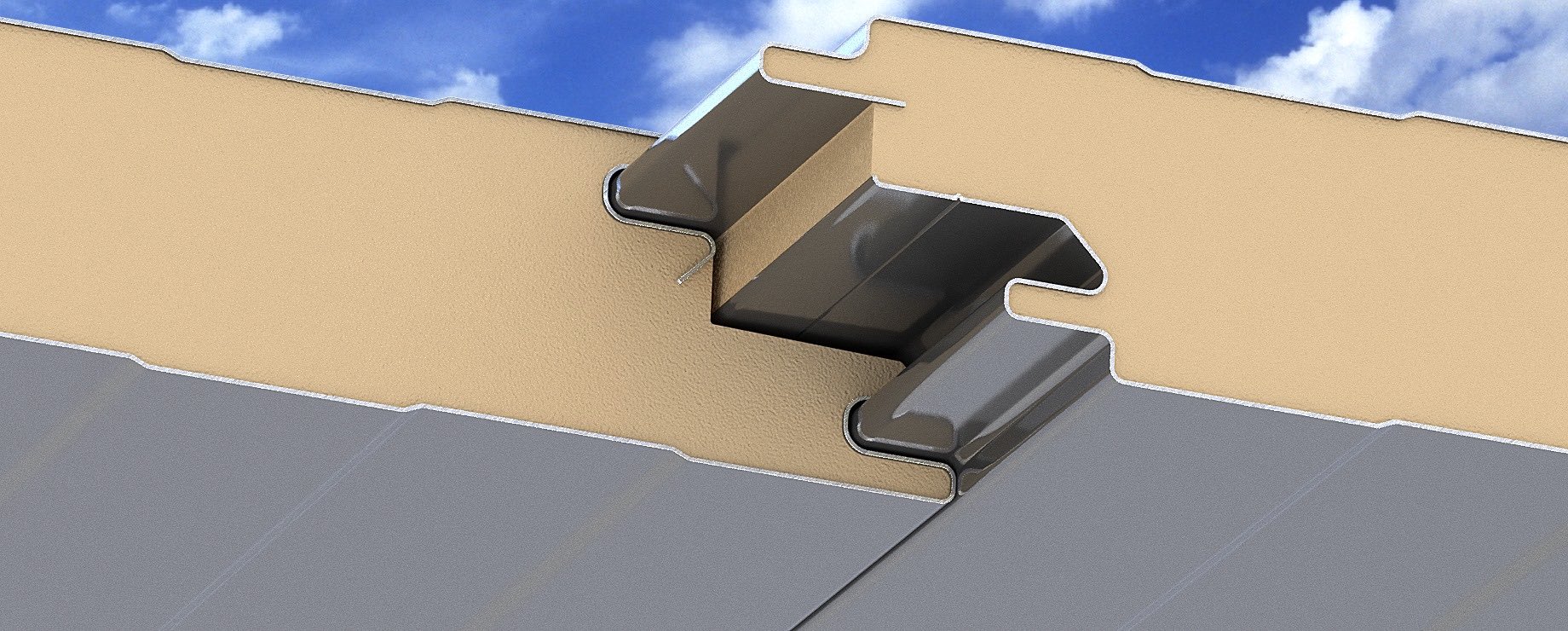

Located in Spanish Fork, the new addition to the facility boasts dimensions of 245’ x 450’ x 37’. Western Steel completed the engineering, including incorporating open webbed fabricated joists set at 12’6″ on center with a 20 Gauge PLN-32 deck and a pinned connection. The structural columns, beams at sidewalls, and the long span joists were engineered to connect to the concrete tilt walls. Other notable features of this addition include:

- Innovative Tilt Wall Design: The concrete tilt walls are crafted to absorb lateral forces from the steel open web trusses.

- Skylights: 45 skylights, each measuring 4’ x 8’, bathe the facility in natural light.

- Structural Depth: With trusses measuring a depth of 124″, they adhere strictly to design codes.

- Clearance: Ensuring efficient operations, the building provides 30’0″ clear under the lowest roof structure as necessitated by the design.

- Roof Perimeter Embeds: These are precisely calculated for the attachment of building steel to the wall for enhanced lateral support.

With such extensive planning and acute design, the SUVSWD transfer station is an advanced waste management facility. Utah’s dedication to the environment is setting the benchmark for future Environmental Recovery Facilities.

Areas We Serve

Our fully-integrated team of Structural Engineers, Detailers, Account Managers, and Estimators provides our clients with optimal resources for timely and cost-effective steel building solutions. This streamlined organizational structure enables us to respond quickly and complete projects within tight timeframes, ensuring timely and cost-effective results that meet even the most critical project needs.

Services Include:

Building Design & Analysis

Structural Engineering

Geotechnical Engineering

Project Management

Material Procurement

Construction Support

Building Solutions Include:

Pre-Engineered Metal Buildings (PEMB)

Conventional Steel Buildings

Hybrid Steel Buildings

Concrete Tilt-Up Steel Buildings

Services Include:

Building Design & Analysis

Structural Engineering

Geotechnical Engineering

Project Management

Material Procurement

Construction Support

Building Solutions Include:

Pre-Engineered Metal Buildings (PEMB)

Conventional Steel Buildings

Hybrid Steel Buildings

Concrete Tilt-Up Steel Buildings

Our Steel Building Types

Conventional Structural Steel Buildings

Our Structural Engineering team streamlines each aspect of structural steel building, from design analysis to material procurement, ensuring customer satisfaction and guaranteed on-time delivery.

Pre-Engineered

Metal Buildings

Also known as pre-eng, this type of building system consists of precision-designed components fabricated to spec at the factory. The factory-cut, ready-to-assemble parts are then shipped to the site, speeding up the construction process.

Hybrid

Steel Buildings

A Western Steel Hybrid Building System combines the secondary members of Pre-engineered Metal Buildings (PEMBs) with Conventional Structural Steel trusses, providing unparalleled design flexibility with installation efficiency

FAQs

Western Steel offers a full range of building solutions for low to mid-rise, new construction projects. Our solutions include pre-engineered metal buildings (PEMBs), conventional or structural steel systems, and hybrid buildings. Our extensive structural engineering expertise on various commercial and industrial projects allows us to create structural solutions efficiently, economically, and flexibly.

We use the latest design techniques and BIM software to engineer structures with efficiency and economy while maintaining the architectural direction. The design process begins with thoroughly understanding the client’s needs and goals. We then value-engineer each project based on functional requirements, budget constraints, and aesthetic preferences. Once we discover these factors, we develop a conceptual design to meet our client’s objectives.

Pre-construction engineering services are essential for a successful project. By obtaining these services, you can ensure that your construction project will be successful and cost-effective. Pre-construction engineering services provide the planning and design work needed to begin a project, allowing engineers to evaluate a construction plan’s feasibility before using any resources.

Engineers identify potential design flaws and develop budget estimates while minimizing risks associated with the development process. During this stage, engineers will review available data, survey sites, and create models that allow them to accurately assess the impact of their proposed designs on the environment and other stakeholders involved in the project.

Conventional Steel is a type of metal building material used in engineering services. An ideal kind of metal, widely used and versatile, making it a perfect choice for many engineering projects. Conventional Steel is refined from iron ore and purified to create a strong and durable material. This type of Steel provides excellent strength, durability, and corrosion resistance compared to other commonly used materials like aluminum or wood.

Conventional Steels versatility makes it useful in many applications, such as fabricating structures, making machinery components, creating architectural elements such as beams or columns, and other industrial equipment.

Structural engineering is a specialized field of engineering that focuses on the design and construction of metal buildings. Structural engineers are responsible for designing these structures’ layouts, architecture, and installation. They must ensure that the building has enough strength to handle any environmental forces it may encounter, such as wind or seismic activity.

Structural engineering aims to create safe structures for use in commercial, industrial, and public spaces. It involves analyzing the environment in which a facility will be built and determining how best to construct it with consideration for safety protocols and aesthetic appeal. Structural engineers assess material properties like tensile strength, stiffness modulus, and shear modulus, among others, to calculate structural loads like dead load and live load, which directly affect design decisions.

Our Western Steel Engineering Division carries E&O (Errors & Omissions) insurance for structural steel building projects. E&O insurance is a type of professional liability insurance designed to protect companies and individuals from claims of negligence or errors and omissions that result in financial losses to a third party. In the context of structural steel building projects, E&O insurance can cover a wide range of risks, including design errors, defective materials or workmanship, and failure to meet the requirements of the project’s plans and specifications.

E&O insurance is a critical component of risk management for structural steel building projects. It protects against claims of negligence or errors and omissions that result in financial losses to a third party and can help to mitigate the risks and liabilities associated with the structural steel industry.

For structural steel building contracts, various types of bonds may be required to ensure the project is completed successfully. Western Steel has the ability to provide bonding for the following:

- Bid bond: This type of bond is required to guarantee that the company submitting the bid will enter into the contract if they are awarded the project.

- Performance bond: A performance bond guarantees that the company will complete the work as specified in the contract and according to the agreed-upon terms, including quality, schedule, and budget.

- Payment bond: A payment bond guarantees that the company will pay all subcontractors, suppliers, and other parties involved in the project as required by law.

At Western Steel, we maintain an excellent credit rating and financial standing, as well as the necessary experience and skills to complete any project successfully. The amount of bonding required for a structural steel building contract will depend on the specific requirements of the contract and the risks involved. We can obtain bonds that are sufficient to cover the full value of the contract, including any potential cost overruns or delays that may occur.

We work closely with reputable bonding agents and surety companies to ensure that our clients have the appropriate bonding coverage and can meet the contract’s requirements.