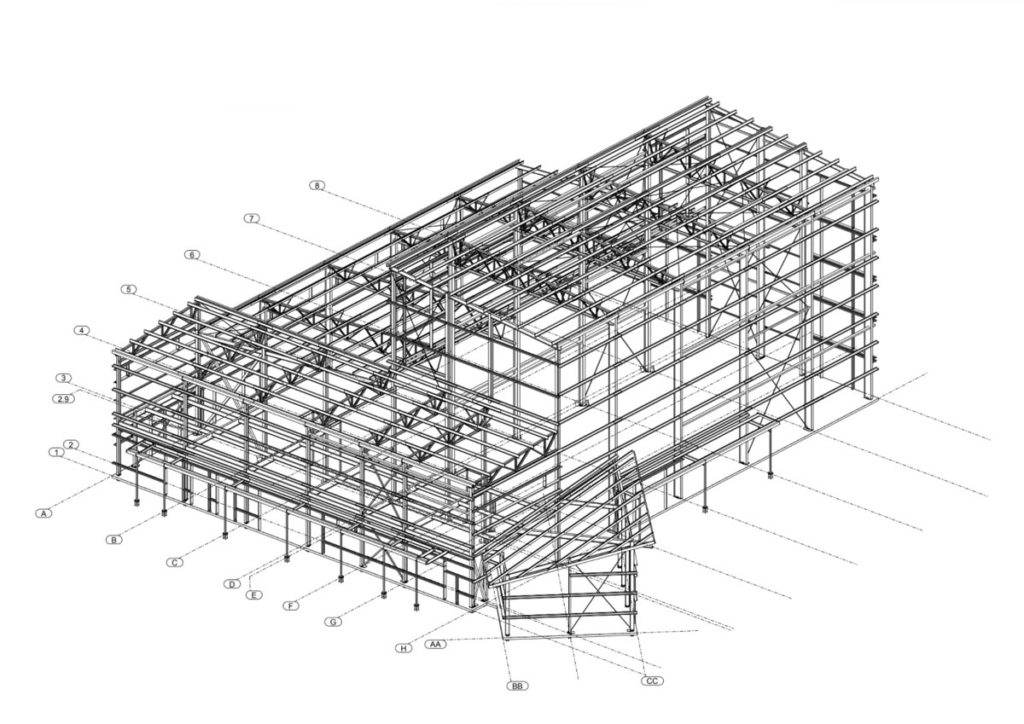

Large & Complex

Steel Building Solutions

Hybrid Steel Buildings

Hybrid steel buildings, which integrate the benefits of both Pre-engineered Metal Buildings (PEMBs) and Conventional Structural Steel Buildings, offer several key advantages:

Cost Efficiency: Combining the precision of factory-based fabrication in PEMBs secondary members and the structural strength of conventional steel, hybrid buildings often prove more cost-effective. There’s less material waste, and the production and installation processes can be more efficient.

Design Flexibility: Unlike PEMBs, which can be somewhat limited in their design possibilities, hybrid buildings offer the customization options of conventional steel structures. This allows for more complex and unique architectural designs

Speed of Construction: The pre-engineered components of a hybrid building system can significantly reduce construction time. These elements can be quickly assembled on-site, reducing the need for extensive field fabrication.

Contact Climbing St. George, UT

The Functionality

Merging the best attributes of Pre-engineered Metal Buildings and Conventional Structural Steel Buildings, our Hybrid Building System offers superior durability, design flexibility, cost-effectiveness, and accelerated installation, ideal for any architectural project.

PEMBs and Conventional Steel Structures have distinct engineering and installation processes. PEMBs use a pre-engineered, three-plate design with factory-cut and pre-drilled steel components for easy assembly. They primarily use I-beams and a bolt-together system but can struggle with complex designs.

Conventional Steel Buildings, however, offer more customization. They use open web steel joists as primary members, with field-cut and drilled I-beams, steel plates, channels, and hollow beams as secondary components. This flexibility comes with higher labor costs and material usage due to onsite fabrication.

PEMBs often cost less due to precise, factory-based fabrication, reducing waste and production time and speeding up installation. Western Steel’s SolutionCentric™ approach blends these methods into our Hybrid Building System. It uses Conventional Steel for primary members and PEMB for secondary ones, combining the design flexibility of open web steel joists with PEMB efficiency to balance design flexibility and cost-effectiveness.