Pre-Engineered Metal Building Systems

At Western Steel, our pre-engineered metal buildings (PEMBs) are highly versatile and customizable, accommodating various layouts and sizes to meet specific needs.

Our design and fabrication process allows for efficient and cost-effective construction, reducing overall project timelines and expenses. Pre-engineered metal buildings offer long-term value and low maintenance requirements, ensuring a lasting investment for our clients.

Areas We Serve

Our fully-integrated team of Structural Engineers, Detailers, Account Managers, and Estimators provides our clients with optimal resources for timely and cost-effective steel building solutions. This streamlined organizational structure enables us to respond quickly and complete projects within tight timeframes, ensuring timely and cost-effective results that meet even the most critical project needs.

Services Include:

Building Design & Analysis

Structural Engineering

Geotechnical Engineering

Project Management

Material Procurement

Construction Support

Building Solutions Include:

Pre-Engineered Metal Buildings (PEMB)

Conventional Steel Buildings

Hybrid Steel Buildings

Concrete Tilt-Up Steel Buildings

Services Include:

Building Design & Analysis

Structural Engineering

Geotechnical Engineering

Project Management

Material Procurement

Construction Support

Building Solutions Include:

Pre-Engineered Metal Buildings (PEMB)

Conventional Steel Buildings

Hybrid Steel Buildings

Concrete Tilt-Up Steel Buildings

Why Choose Western Steel?

At Western Steel, we create practical and aesthetic steel buildings that blend form and function. Our Engineering Division employs advanced BIM modeling software to analyze and design our diverse range of steel building solutions. We proudly showcase the capabilities of our pre-engineered, conventional, hybrid, and concrete tilt-up steel buildings, emphasizing design flexibility, sustainable materials, and optimal performance.

Unleashing the Steel Buildings of the Future

Technology is revolutionizing architecture, enabling architects to design and construct buildings in unprecedented ways. We are pushing boundaries and allowing for new aesthetic experiences. Our team utilizes innovative technology to disrupt traditional construction methods like concrete tilt or brick and mortar, achieving greater design flexibility than previously thought possible.

Pre-construction Services

Western's pre-construction services include researching building codes and regulations, determining load requirements, and identifying potential risks. Western's Engineering team ensures steel components fabricated for the project meet design and safety standards for the construction site.In addition, we consider the project costs and timeline creating a detailed budget for materials and other related expenses.

Material Procurement & Logistics

Guaranteed on-time delivery, superior customer service, extensive design options and excellent supply chain management have made Western Steel the smart choice for low to mid-rise, new construction projects. With multiple factory affiliates throughout North America and a proven logistics team specializing in motor and ocean freight, we are your source for steel buildings in North America and beyond.

Pre-Eng & Hybrid Steel

Solutions

Ideal for low-rise, large & complex steel building projects.

Structural Steel

Solutions

Ideal for mid-rise, large & complex steel building projects.

Western Steel's

Pre-Eng & Hybrid Solutions 14 to 18 weeks Until Delivery

Week 1

Project Discovery

Discuss Goals

Estimating

Building Order

Guaranteed Price Lock

Engage Material Supplies

Week 2

Design Approvals

Design Approvals

Schedule Fabrication

Set Delivery Date

Week 3

Engineering Begins

Engineering Begins

Engineer Stamped Plans Deliverable in 2 to 4 weeks

Weeks 4 to 6

Permitting & Bids

Receive Engineer Stamped Plans

Utilize Plans for Permitting (by Client) Utilize Plans for Builder Bids (by Client)

Weeks 7 to 14

Building Fabrication

Material Procurement & Fabrication Complete Site Work (by Builder)

Design & Install Foundation (by Builder)

Weeks 14 to 18

Steel Building System Delivery

Building System Delivery

Inventory Materials (by Builder) Stage Materials (by Builder)

Steel Installation Begins (by Builder)

FAQs

Pre-engineered metal buildings (known as PEMBs and also referred to as Steel Buildings) are building systems with components pre-fabricated at the factory that are designed to be assembled quickly and efficiently at the construction site. These buildings consist of steel components engineered to fit together precisely as a building system since each component is pre-cut and pre-drilled at the factory to exact specifications, ensuring a streamlined construction process.Western Steel offers a full range of building solutions for low to mid-rise, new construction projects. Our solutions include pre-engineered metal buildings (PEMBs), conventional or structural steel systems, and hybrid buildings. Our extensive structural engineering expertise on various commercial and industrial projects allows us to create structural solutions efficiently, economically, and flexibly. We use the latest design techniques and BIM software to engineer structures with efficiency and economy while maintaining the architectural direction. The design process begins with thoroughly understanding the client’s needs and goals. We then value-engineer each project based on functional requirements, budget constraints, and aesthetic preferences. Once we discover these factors, we develop a conceptual design to meet our client’s objectives.

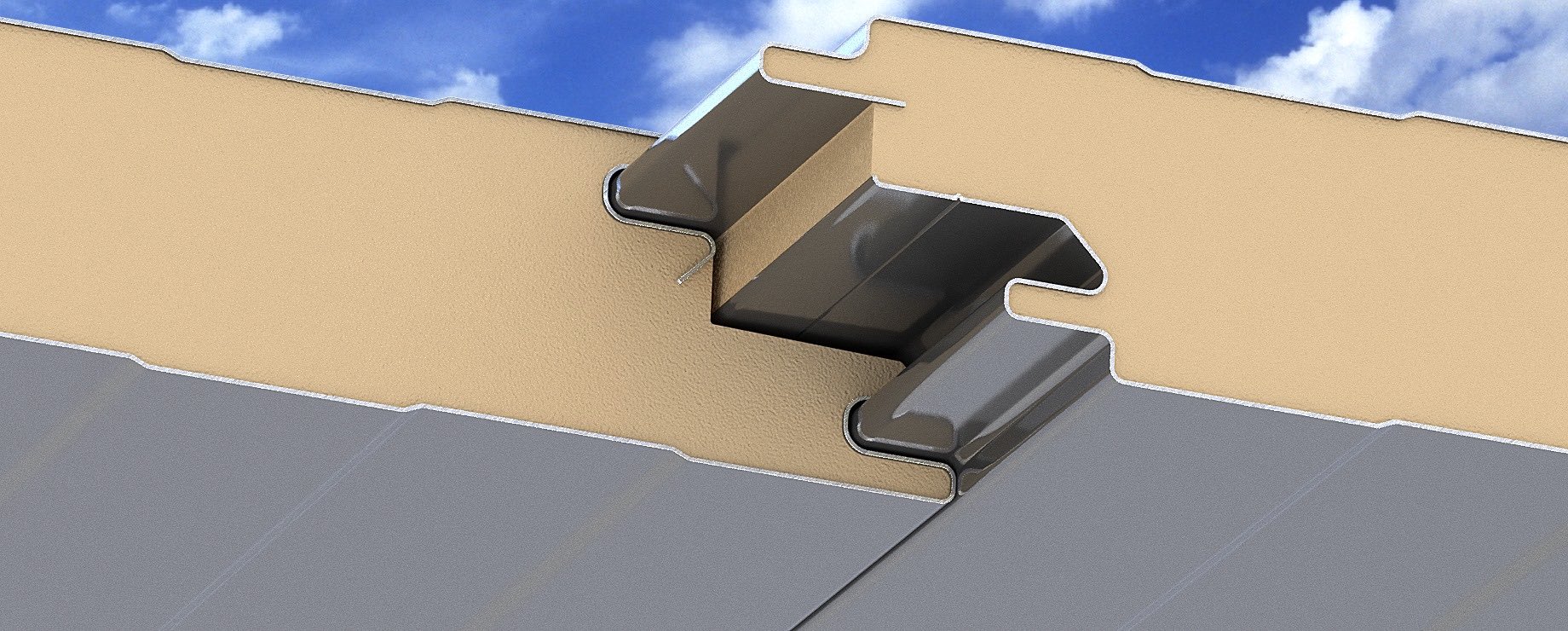

Pre-engineered steel buildings offer exceptional customization options to meet specific design requirements precisely. These buildings can be tailored in size, shape, layout, and aesthetic preferences. Choices abound for doors, windows, insulation, roofing, and exterior finishes, including incorporating exterior insulated metal panels.

Insulated metal panels provide excellent thermal insulation properties, regulating the building’s temperature and enhancing energy efficiency. Specifically designed for installation on the exterior of steel buildings, these panels ensure a comfortable interior environment with enhanced insulation capabilities.

The roof style of pre-engineered steel buildings is also customizable, with options like clerestory, monitor, and gambrel roof lines, allowing for design versatility and architectural variety as seen in these completed projects.

Interior mezzanines are commonly integrated into pre-engineered steel buildings, creating additional usable space. These mezzanines can be customized for diverse purposes such as storage, offices, or workspaces, offering flexibility per specific requirements.

Thanks to their extensive customization options, pre-engineered steel buildings offer a versatile and adaptable solution, including exterior insulated metal panels, interior mezzanines, and customizable roof styles.

Pre-engineered steel buildings offer several benefits, such as cost-effectiveness, durability, and versatility. They are typically less expensive than traditional construction methods, require less maintenance, and can be customized to suit various applications, including warehouses, factories, offices, etc.

The construction time for a pre-engineered steel building depends on various factors, including the size and complexity of the structure. However, one of the key advantages of these buildings is their faster construction time compared to conventional buildings. Generally, smaller steel buildings can be erected in weeks, while larger projects may take a few months.

Yes, pre-engineered steel buildings can be designed to be energy-efficient. They offer excellent insulation options to minimize heat transfer, reducing heating and cooling costs. Additionally, natural lighting, ventilation systems, and energy-efficient fixtures can be incorporated into the building’s design to enhance energy efficiency further.

Yes, pre-engineered steel buildings are suitable for a wide range of climates. Steel is a durable material that can withstand various weather conditions, including high winds, heavy snow loads, and seismic activity. With proper insulation and ventilation systems, these buildings can provide a comfortable interior environment in both hot and cold climates.

Primary Framing Options Pre-Engineered Steel Building Systems

Primary frames are designed for full bay loading and span the width of a building. For the pre-engineered systems these primary members are typically I-beams. Frame systems include clear-span, multi-span and lean-to frames in tapered or straight format. Each steel frame system is custom engineered to meet specifications and local building codes.

Tapered Frames vs. Straight Frames: The tapered frame is generally used in column free applications from 40’ to 250’. The straight column rigid frame is designed for maximum efficiency of interior space. Building widths up to 250’ are available with the option of straight columns instead of tapered columns. Lean-to structures are also available for future expansion or additional space if the original main structure had been designed to support the additional load of a lean-to.

Crane Buildings: Crane buildings are complex PEMB or hybrid structural building systems consisting of the crane with trolley and hoist, crane rails, and crane runway beams, structural supports, stops and bumpers.

Gable Clear Span Primary Frame

Single Slope Clear Span Frame

Multi-span Primary frames

Lean-To Primary frames

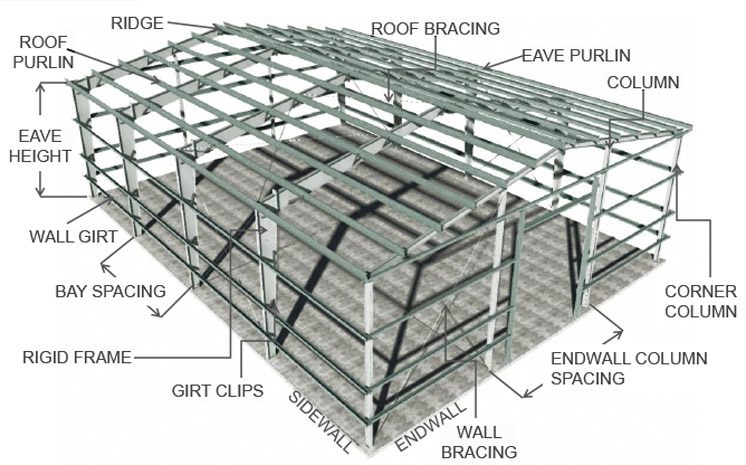

Pre-Engineered Metal Building

System Diagram

Bay Spacing – Each space or interval between the rigid frames.

Sidewall Column – Main member used in vertical support position to transfer loads from main purlins or rafters into the foundation.

Eave Height – Vertical dimensions from finished floor to eave.

Eave Purlin – Structural member located at the eave of a building that supports roof and wall paneling and may transfer bracing loads to frames.

Endwall – Exterior wall that is parallel to the interior rigid frame.

Endwall Column – Vertical member located at the endwall of a building that supports the girts.

Girt – Horizontal structural member that is attached to sidewall or endwall columns to support paneling.

Girt Clips – Connection clips used to attach the back side of a panel to a structural beam.

Ridge – Horizontal line formed by opposing sloping sides of a roof running parallel with the building length. Generally the highest point of building without parapet walls.

Rigid Frame – Structural frame consisting of members joined together with moment connections to render the frame stable with respect to the design loads, without the need for bracing in its plane.

Roof Purlin – Horizontal structural member that supports roof covering.

Sidewall – Exterior wall that is perpendicular to the frames of a steel building system.

Our Steel Building Types Structural Pre-Engineered Concrete Tilt-Up

Conventional Structural Steel Buildings

Our Structural Engineering team streamlines each aspect of structural steel building, from design analysis to material procurement, ensuring customer satisfaction and guaranteed on-time delivery.

Pre-Engineered

Metal Buildings

Also known as pre-eng, this type of building system consists of precision-designed components fabricated to spec at the factory. The factory-cut, ready-to-assemble parts are then shipped to the site, speeding up the construction process.

Concrete Tilt-Up

Steel Buildings

Discover the strength and versatility of our cutting-edge steel building solutions paired with the concrete tilt-up constructions. Merging the best of both worlds, we deliver unparalleled durability, design flexibility, and cost efficiency.