Hybrid Steel Buildings: Combining Precision and Strength

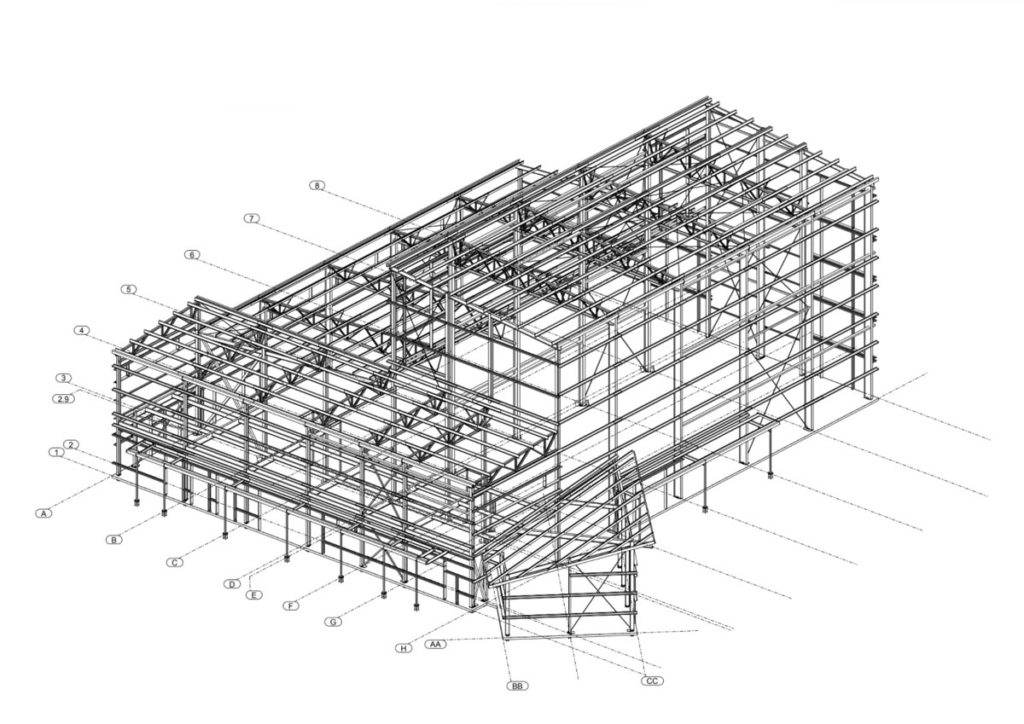

Our hybrid steel buildings offer the best of Pre-engineered Metal Buildings and Conventional Steel Buildings for maximum efficiency and strength.

Cost Efficiency

- Precision of PEMBs: Utilizes the exacting standards of PEMBs for secondary members.

- Structural Strength: Combines the enduring strength of conventional steel.

- Reduced Material Waste: Minimizes waste through optimized design and production.

- Efficient Production and Installation: Streamlines both manufacturing and assembly processes.

Flexible Designs

- Customizable: Offers the same level of customization as conventional steel, accommodating unique design requirements.

- Architectural Support: Facilitates complex and intricate architectural designs with ease.

Fast Construction

- Pre-engineered Components: Accelerates construction with pre-engineered, precision-built components.

- Rapid On-Site Assembly: Ensures quick assembly to reduce construction time.

- Minimized Field Fabrication: Reduces the need for extensive on-site modifications.

Contact Climbing St. George, UT

Hybrid Steel Construction

As the name implies, hybrid steel construction combines both pre-engineered and conventional methods to meet the client’s needs. Western Steel provides some of the most comprehensive hybrid structures in the country, tailored to each client’s unique requirements.

PEMBs and Conventional Steel Structures have distinct engineering and installation processes. PEMBs employ a pre-engineered, three-plate design, utilizing factory-cut and pre-drilled steel components for convenient assembly. They primarily use I-beams and a bolt-together system but may face challenges when dealing with complex designs.

On the other hand, Conventional Steel Buildings provide greater customization options. They utilize open web steel joists as primary members, along with field-cut and drilled I-beams, steel plates, channels, and hollow beams as secondary components. However, this flexibility results in higher labor costs and increased material usage due to on-site fabrication.

Open Web Steel Joists

Joists from conventional steel construction are the primary frame of a Western Hybrid Building System and they are used to support the floors or roof of a building. A steel joist must be designed to withstand forces and stress while minimizing weight, space requirements, and material costs. Different types of joist designs are available based on loading and mounting configurations. Open-web steel joist (OWSJ) consists of two parallel members, or chords, with a repeating, triangular web structure located between the chords.

Our Steel Building Types Conventional Pre-Engineered Hybrid Concrete Tilt-Up

Pre-Engineered

Metal Buildings

Also known as pre-eng, this type of building system consists of precision-designed components fabricated to spec at the factory. The factory-cut, ready-to-assemble parts are then shipped to the site, speeding up the construction process.

Hybrid

Steel Buildings

As the name implies, hybrid steel construction combines both pre-engineered and conventional methods to meet the client’s needs. Western Steel provides some of the most comprehensive SolutionCentric™ hybrid structures in the country, tailored to each client’s unique requirements.

Conventional Structural Steel Buildings

Our Structural Engineering team streamlines each aspect of structural steel building, from design analysis to material procurement, ensuring customer satisfaction and guaranteed on-time delivery.

Concrete Tilt-Up

Steel Buildings

Discover the strength and versatility of our cutting-edge steel building solutions paired with the concrete tilt-up constructions. Merging the best of both worlds, we deliver unparalleled durability, design flexibility, and cost efficiency.

Project Spotlight

Project Spotlight: Dutch Goat Auctions Distribution Facility

These large facilities consist of state-of-the-art technology and a variety of building types and sizes to support processing orders. Conventional construction methods such as tilt or structural steel are outdated for this type of structure. At Western Steel Buildings, our building systems bring our clients incredible cost and time savings.

Project Spotlight: Novae Manufacturing Facility

Novae’s New Facility by Western Steel Buildings in Collaboration with Michael Kinder and Sons Construction.

Project Spotlight: Blue Sky Ranch Riding Arena

Explore Western Steel’s state-of-the-art indoor riding arena at the Blue Sky Equestrian Center, blending elegant design with functionality.

Project Spotlight: BZI Steel

At Western Steel, we innovate complex and adaptable steel buildings for sophisticated projects.

Project Spotlight: Big Island Grown

Big Island Grown is an environmentally sustainable business utilizing solar on the roof and hydroelectric to power the facility.

Project Spotlight: Jayco Hawaii

Western Steel’s pre-engineered solutions in Hawaii for Jayco emphasize open floor plans and ample natural light to enhance productivity and efficiency.

Questions from our Customers:

What are hybrid steel buildings, and how do they differ from traditional metal buildings?

Hybrid steel buildings combine the strength of metal buildings with the versatility of traditional construction methods. They use a steel framework for durability while allowing for greater design flexibility and the integration of various materials. This makes hybrid steel buildings more adaptable for complex architectural designs. They also offer cost efficiency by optimizing both steel and conventional construction techniques, delivering enhanced performance in terms of strength, energy efficiency, and durability.

What factors influence the prices of steel buildings?

Steel building prices are affected by several factors, including the size and complexity of the design, the quality and type of steel used, and the condition of the construction site. Custom features, such as unique sizes, additional insulation, or architectural elements, can increase costs. Additionally, market conditions and fluctuations in steel prices play a role in determining overall costs for metal buildings and hybrid steel buildings.

What materials are used in hybrid steel buildings?

Hybrid steel buildings combine pre-engineered components like PEBs and conventional steel materials such as open-web steel joists and hollow steel sections for secondary components.

How long does it take to construct a hybrid steel building?

Construction time is reduced through the use of pre-engineered components and rapid on-site assembly, ensuring quicker completion compared to traditional methods.

Can I become a vendor with Western Steel?

Yes, to become one of our preferred vendors, simply fill out the application and submit. Our one of team members will reach out to you.