Custom Engineered Frame Systems: Tailored to Your Building Needs

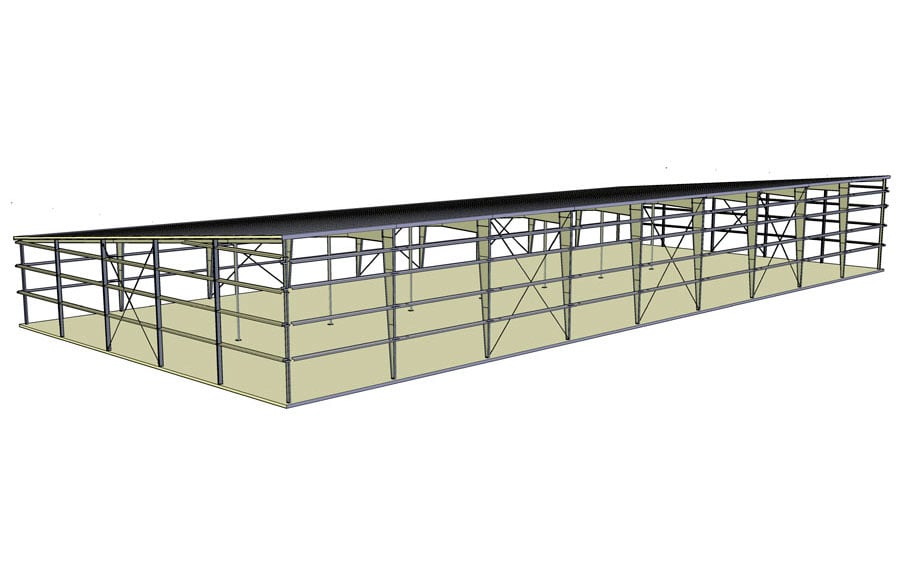

Primary frames are designed for full bay loading and span the width of a building. For the pre-engineered systems these primary members are typically I-beams. Frame systems include clear-span, multi-span and lean-to frames in tapered or straight format. Each steel frame system is custom engineered to meet specifications and local building codes.

Tapered Frames vs. Straight Frames: The tapered frame is generally used in column free applications from 40’ to 250’. The straight column rigid frame is designed for maximum efficiency of interior space. Building widths up to 250’ are available with the option of straight columns instead of tapered columns. Lean-to structures are also available for future expansion or additional space if the original main structure had been designed to support the additional load of a lean-to.

Crane Buildings: Crane buildings are complex PEMB or hybrid structural building systems consisting of the crane with trolley and hoist, crane rails, and crane runway beams, structural supports, stops and bumpers.

Gable Clear Span Primary Frame

Single Slope Clear Span Frame

Multi-span Primary frames

Lean-To Primary frames

Structural Framing Systems

Flexible Designs

With a variety of framing systems, we will Value-Engineer a design to meet your specific requirements with the overall cost in mind. At Western, we understand design flexibility is crucial to the success of a project. We can produce a standard box design, or provide a completely custom prefab structure with parapet walls, attachment buildings, concrete or insulated panel.

Durable Buildings

Western Steel structures last longer than traditional construction methods. Steel is not susceptible to mold, termites or wood rot. Our buildings can be designed to withstand hurricane force winds up to 180 mph. We can engineer our structures for the most extreme conditions such as heavy snow, high winds, or intense seismic activity. The structural members can be hot-dip galvanized for the ultimate protection from rust.

Naturally Greener Buildings

As much as 90% of the steel that is used in our fabrication process is recycled steel. Our buildings are engineered to make them easy to insulate, with tighter fittings around doors and windows allowing for lower operating costs. Pre-engineered steel buildings mean less construction waste, overall a much better choice for the environment.

Cost-effective

Our prefab buildings can save on design, construction, and maintenance costs. Western buildings bolt-together on the job site, allowing faster install times that are streamlined.

Fire-resistant

Steel has a melting point of approx. 2,500 degrees. This makes it one of the best fire-resistant materials to use in new construction.

Clear Span

Column-free interiors provide unobstructed space. They are ideal for equestrian arenas, sports arenas, aviation hangars, retail space, manufacturing facilities, and more.

Multi-Span

Lean-to